Small UK company? £10k grants up to 40% off an LED project available. Click here for more info

call us on +44 (0)1483 688170

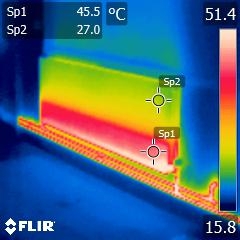

Thermal imaging uncovers electrical system defects though differences in heat signatures. By surveying the electrical system using a thermal camera will highlight any defects. Examples of these include identification of loose terminals on breakers, overloaded cables, incorrect wiring and other technical issues such as harmonics, sags and lags.

Combining our electrical knowledge, auditing ability and thermographic surveying techniques we produce detailed reports that identify electrical problems before they become major issues.

The surveys can be either done as a once off, manual report or, using our IoT based conditioning reporting system, on a real-time and event driven basis.

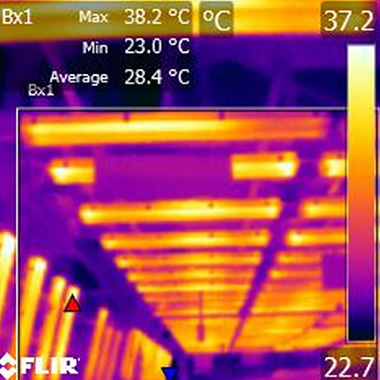

Ecopare can provide a building envelope inspection that includes all internal and external areas. This allows for assessment and identification of areas of energy loss and possible building defects such as missing insulation, heat bridges, construction defects and age-related wear and tear.

All reports provide detailed information on category of defect, possible remedial actions and, using our energy auditing experience, energy waste costs. This is useful in determining a payback model for fixing the defect.

We also provide thermal-activity reporting where, over a period of time we capture the thermal dynamics of the building to identify real occupancy vs perceived usage, building heating management system schedules and “human” energy loss indicators. These indicators include opening windows, leaving heating/cooling running and other overriding factors.

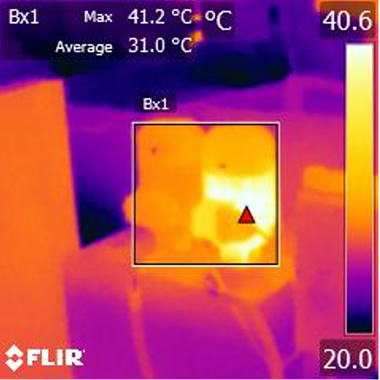

The condition of a machine, pump or motor can be quickly seen with the use of a thermal survey. This is because overheating is usually a symptom before catastrophic failure of a component.

Ecopare has developed a standard plant and machinery thermography survey that will identify possible defects and provide recommended remedial action.

We recommend this survey is undertaken at least once a year but our larger clients, with many electrical assets, undertake this once a month.

Typical areas to be surveyed:

Ecopare also offers a real time IoT based thermographic solution that continuously monitors the temperature of an asset or group of assets. With a configurable alarm based threshold system, multiple alerts can be sent when certain criteria, such as a spike in temperature, are met.

Over time we have built a library of examples of defects that we have uncovered using thermal imaging.